Ekso Bionics: Work faster, smarter, safer.

(PA, NJ, MD, DE, VA, WV)

www.eksobionics.com

www.eksobionics.com

|

The U.S. spends $21 billion per year on workplace-related injuries that drain productivity. Construction workers are 5x more likely to report poor health. 20% of construction workers report severe pain.

EksoZeroG™ helps ease the physical burden on construction and electrical workers. With EksoWorks' innovative exoskeleton technology, your workers can now complete heavy hand tool tasks with less fatigue, better workmanship, and fewer workplace injuries.

|

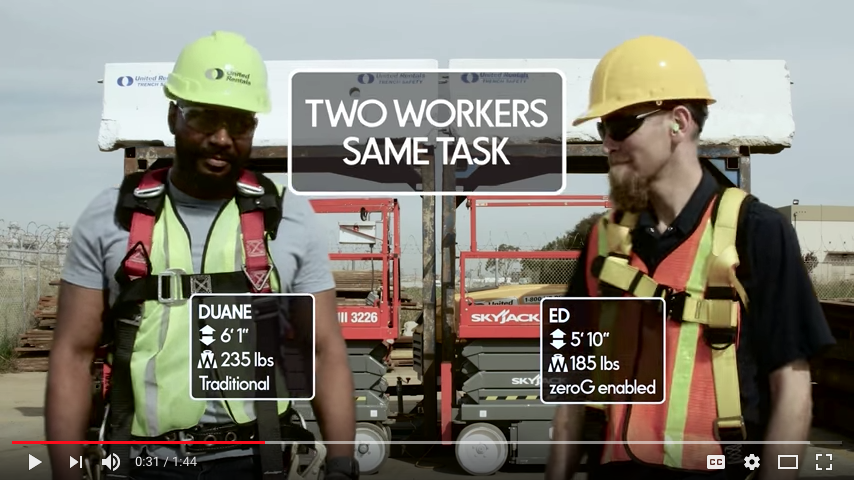

EksoZeroG Head to Head Competition

|

How the EksoVest Is Changing the Labor-Intensive Automotive Industry

|

Over 100 years ago, the moving assembly line, invented by Ford Motor Company under the leadership of Henry Ford, revolutionized automotive production. Today, Ford is still committed to utilizing groundbreaking technologies to further revolutionize mass production.

The physical demands of repetitive overhead work takes its toll on workers. Some workers on the assembly line lift their arms an average of 4,600 times per day, or about 1 million times per year, increasing the possibility of fatigue or injury. That’s where the EksoVest comes in. Ford and Ekso Bionics partnered to explore how this upper body exoskeleton that elevates and supports a worker’s arms can help. By reducing the strain on a worker’s body, he/she not only feels better at the end of every day, it also reduces the likelihood that the worker will sustain injury. Jobs get completed to a higher level of quality, in a shorter amount of time, increasing both productivity and morale. |

The Ford PartnershipFord initially partnered with EksoWorks to pilot the EksoVest in two U.S. plants. As a result, use of the EksoVest will be expanded to plants in other regions, including Europe and South America.

Coincidentally, Ekso Bionics is headquartered in the former Richmond, California Ford factory, which opened in 1931 and was the largest auto assembly plant on the West Coast. The plant manufactured Model A and AA vehicles before it was retooled during WWII to process tanks and jeeps at the direction of Franklin D. Roosevelt. Now, over 80 years later, it is home to cutting-edge exoskeleton technology that is changing the automotive industry. |

“Collaboratively working with Ford enabled us to test and refine early prototypes of the EksoVest based on insights directly from their production line workers. The end result is a wearable tool that reduces the strain on a worker’s body, reducing the likelihood of injury, and helping them feel better at the end of the day—increasing both productivity and morale. The EksoVest is now ready to help workers around the world.”

—RUSS ANGOLD, CO-FOUNDER AND CTO, EKSO BIONICS |